Last week PDE 4 took a trip down to Plastic Moldings in Irvine, I thought I’d upload a few pictures from the trip.

PM Ltd. manufacture a variety of products, from handle grips to brake covers for cranes, and employ a number of different processes to do so. Last Thursday, a member of their customer service team – Barry, was kind enough to give us a tour of their facilities.

Plastic pellets pre melting for manufacture.

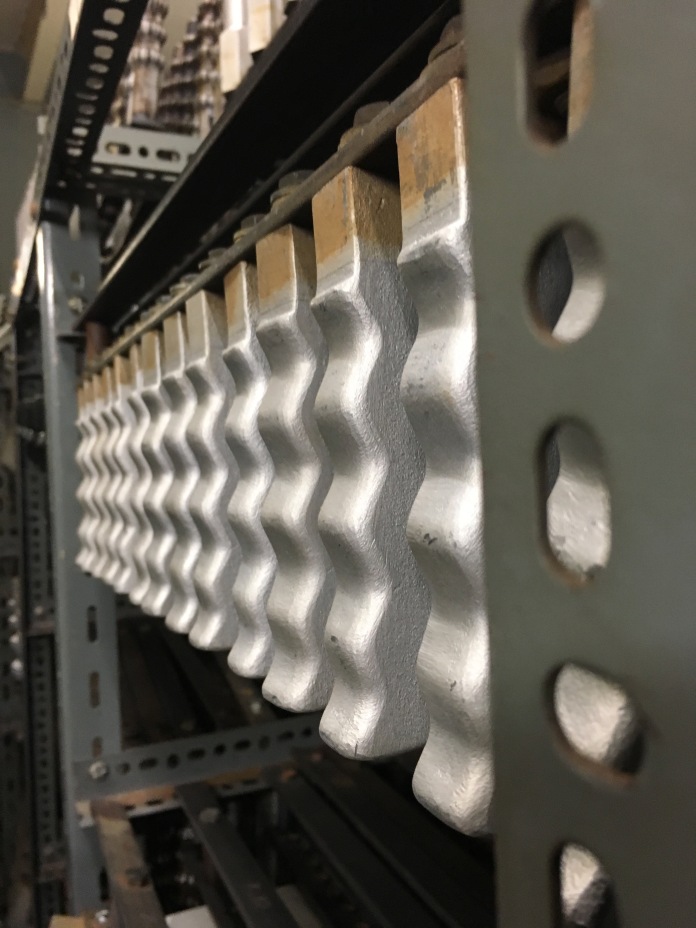

Cast aluminium die – these are dipped in PVC to create rubberised handle grips.

This is liquid PVC, I was quite surprised to see it in this state at room temperature.

A piece created using the dip coating process.

Moving on from the dip-coating, we saw floats made by rotational molding.

We later saw the workshop where they create templates that are used to fabricate some of the cast aluminium die used in the molding processes. I was pleasantly surprised to find that many of these templates were made by hand – especially after our recent lecture involving the demise of skilled manufacture.

The final stop on the tour was the vacuum forming workshop. Barry explained to us that after the plastic sheets are heated and shaped, all of the finishing is completed by hand. Custom built wooden templates are used – a clever solution that allows them to achieve accurate results repeatedly. The finished components had a very machine-manufactured appearance, which is often the case with plastic products, so it was refreshing to learn that there is still an element of handicraft involved in the process.